Sugar Coating of Tablets

Tablet coating is the process where coating material is applied to the surface of the tablet to achieve the desired properties of dosage form over the uncoated tablets. The advantages of coating are listed below.

- Improving taste, odour, and colour of the drug

- Improving ease of swallowing by the patient

- Improving product stability

- To protect against the gastric environment

- To improve mechanical resistance of the dosage form

- Modifying release properties

Sugar Coating

Sugar coating of tablets involves the successive application of sucrose-based coating formulations...

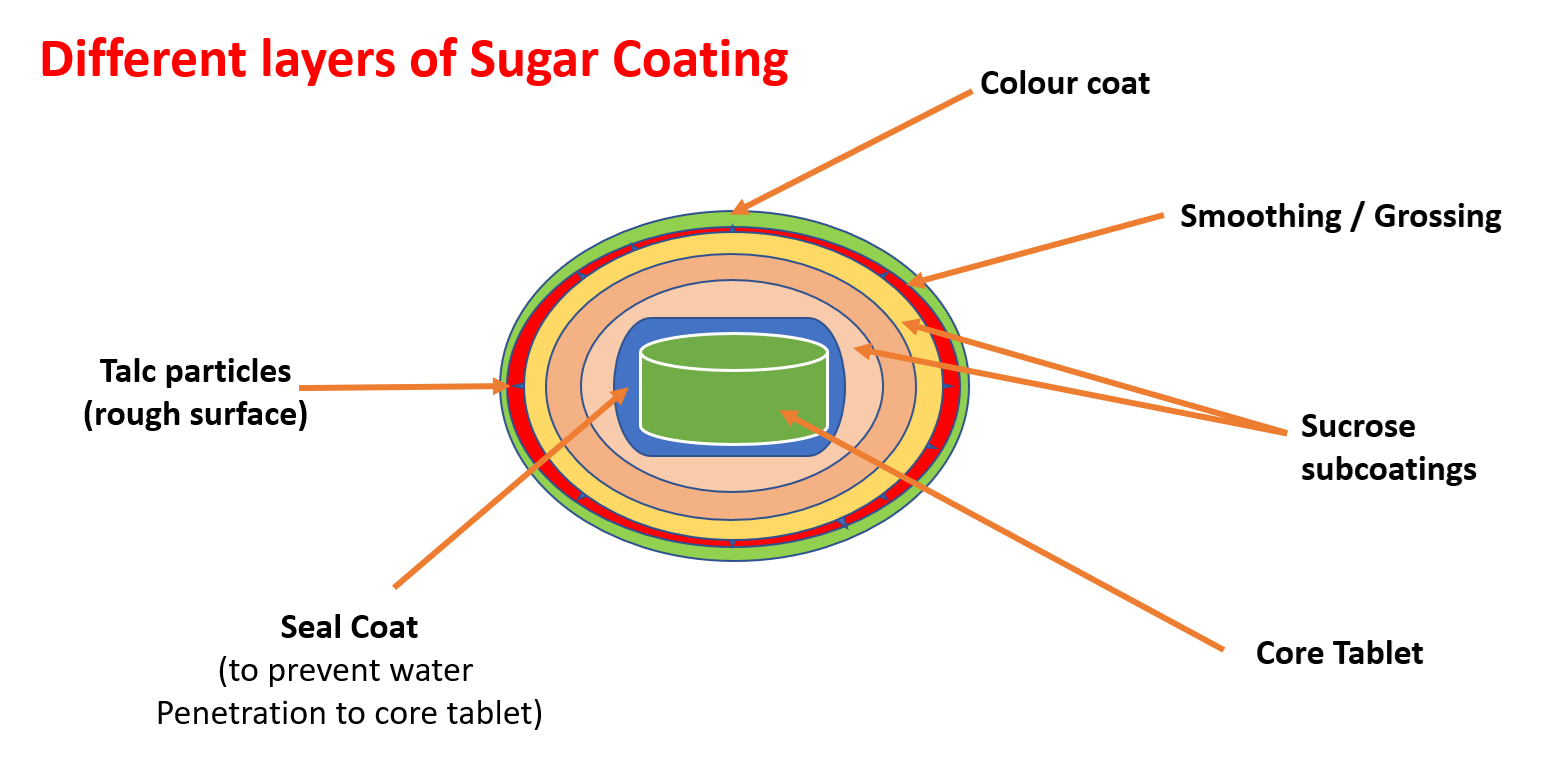

Sugar coating is a multistage process and can be divided into the following steps:

- Sealing: It involves hardening the external surface of the tablet...

- Subcoating: To build up the shape and size of the tablet

- Smoothing: Smoothing out the coated area while increasing the size...

- Colouring: Provides the tablet with the appropriate colour

- Polishing: To give the tablet a glossy appearance

- Printing: To create markings like name, logo or identification mark

Sealing

Sugar coatings are aqueous formulations that are poured directly onto the tumbling tablets. Hence water has an opportunity to penetrate directly into the tablet cores, potentially affecting the core tablet’s stability and possibly cause premature tablet disintegration. To prevent these problems, the cores are usually sealed initially with a water-proofing or sealing coat.

tablet core is usually sealed with a thin continuous film of a poorly water-soluble polymer such as shellac or cellulose acetate phthalate. This sealing coat serves to protect the tablet core and its contents from the aqueous fluids used in the subsequent steps of the sugar-coating process. Traditionally, alcoholic solutions of shellac were used for this purpose although the use of synthetic polymers, such as cellulose acetate phthalate or poly (vinyl acetate phthalate), is also favoured.Subcoating

The sugar subcoating is applied to round the edges and build up the tablet size. Sugar coating can increase the tablet weight by 50 to 100%. The subcoating step consists of alternately applying a sticky binder solution to the tablets followed by a dusting of subcoating powders and then drying.

Subsequent subcoats are applied in the same manner until the tablet edges have been covered and the desired thickness is achieved. For spray processes for subcoating, a subcoating suspension containing both the binder and the insoluble powder is sprayed intermittently on the tablet bed. In addition, antiadherents such as talc may be used to prevent tablets sticking together, and polysaccharide gums, such as gum acacia, may also be added as a binder in order to reduce brittleness.Syrup (Smoothing/Colour) Coating

The subcoating stage often leaves the tablet surface rough and uneven. To make the surface smooth for the color coating, a layer of sucrose syrup is applied, and sometimes, gum acacia or gelatin is added to improve adhesion.

This syrup is usually mixed with titanium dioxide, which helps give the tablets a white and uniform base before coloring, this ensures that further colour coats will become bright and even. Warm air is passed in the coating pan to remove excess moisture. The syrup layer hardens into a smooth coating. Apply several heavy-coloured syrup coats in a similar manner until a specific tablet volume is attained and tablet become smoother and rounder.Colouring

Colour coatings usually consist of sucrose syrups. containing the requisite colouring materials. Sugar-coating colourants may be subdivided into either water-soluble dyes or water insoluble pigments.

-

Preparation of Colour Syrup

- A sucrose syrup solution is prepared.

- Water-soluble dyes (like FD&C colours) or insoluble pigments (like titanium dioxide, iron oxides, lakes) are added.

- Sometimes a mix of both is used to get the desired shade.

- • The colour syrup is applied in small amounts onto the smooth, syruped tablets in the coating pan.

- Tablets are rotated to spread the colour evenly.

Warm air is blown to dry the coating and fix the colour on the surface. The process is repeated many times until the required depth and uniformity of colour is achieved.

Water-soluble dyes: e.g., tartrazine, sunset yellow. Insoluble pigments (lakes): e.g., titanium dioxide (white), iron oxides (red, yellow, brown), indigo.Polishing

The desired lustre is obtained in this final step of the sugar-coating process. The tablets can be polished in clean standard coating pans, or canvas-lined polishing pans.

Once the colour coating layers have been applied and dried, the tablet surface tends to be smooth but somewhat dull in appearance. To achieve the glossy finish, a final stage involving the application of waxes is employed. Suitable waxes include beeswax, carnauba wax or candelilla wax applied as finely ground powders or as suspensions/solutions in an appropriate organic solvent. Tablet coatings achieve their lustre during the polishing phase. In the canvas-lined pans, the lining is used to transfer the waxes to the tablet surface and to provide a frictional rubbing movement that occurs when tablets roll and tumble against each other and against the walls of the coating pan.Printing

In the case of sugar-coated tablets, the markings (name, logo or any identification mark) cannot be embossed or engraved because of the thick coating. So, the identification is done by printing on the tablet surface using special edible inks.

The most common method is the offset gravure printing process, but modern techniques like ink-jet printing and pad printing are also widely used.